走进至茂科技

⾄茂科技为新能源制造与各类型检测设备领域的专业制造商,始终秉持“振兴⺠族⼯业,成就国际品牌”为奋⽃⽬标,以“宁以⾼品质昂头,不以低品质驼背”的企业理念,“永续经营”的企业宗旨来不断完善发展,持续改⾰创新。

专精特新中小企业

专利和软著

专利产品

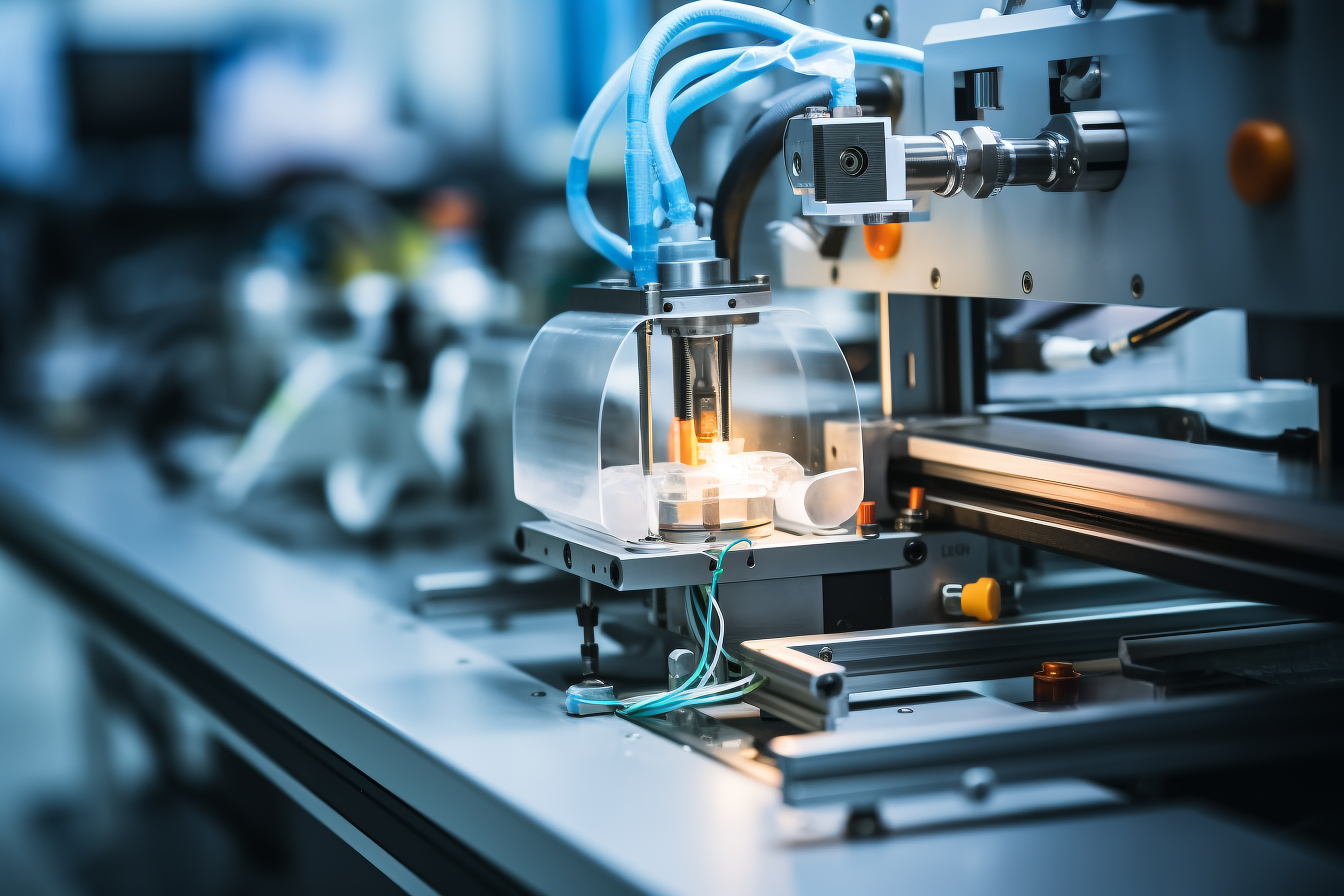

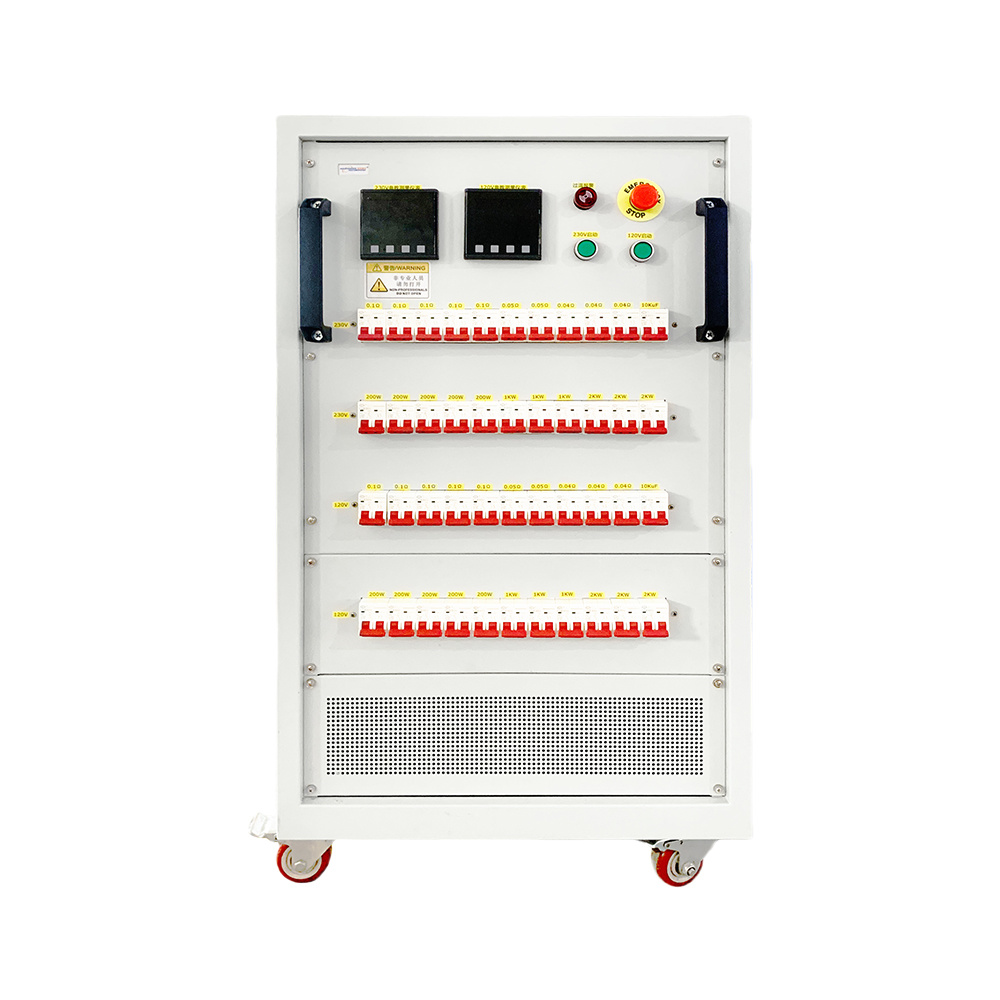

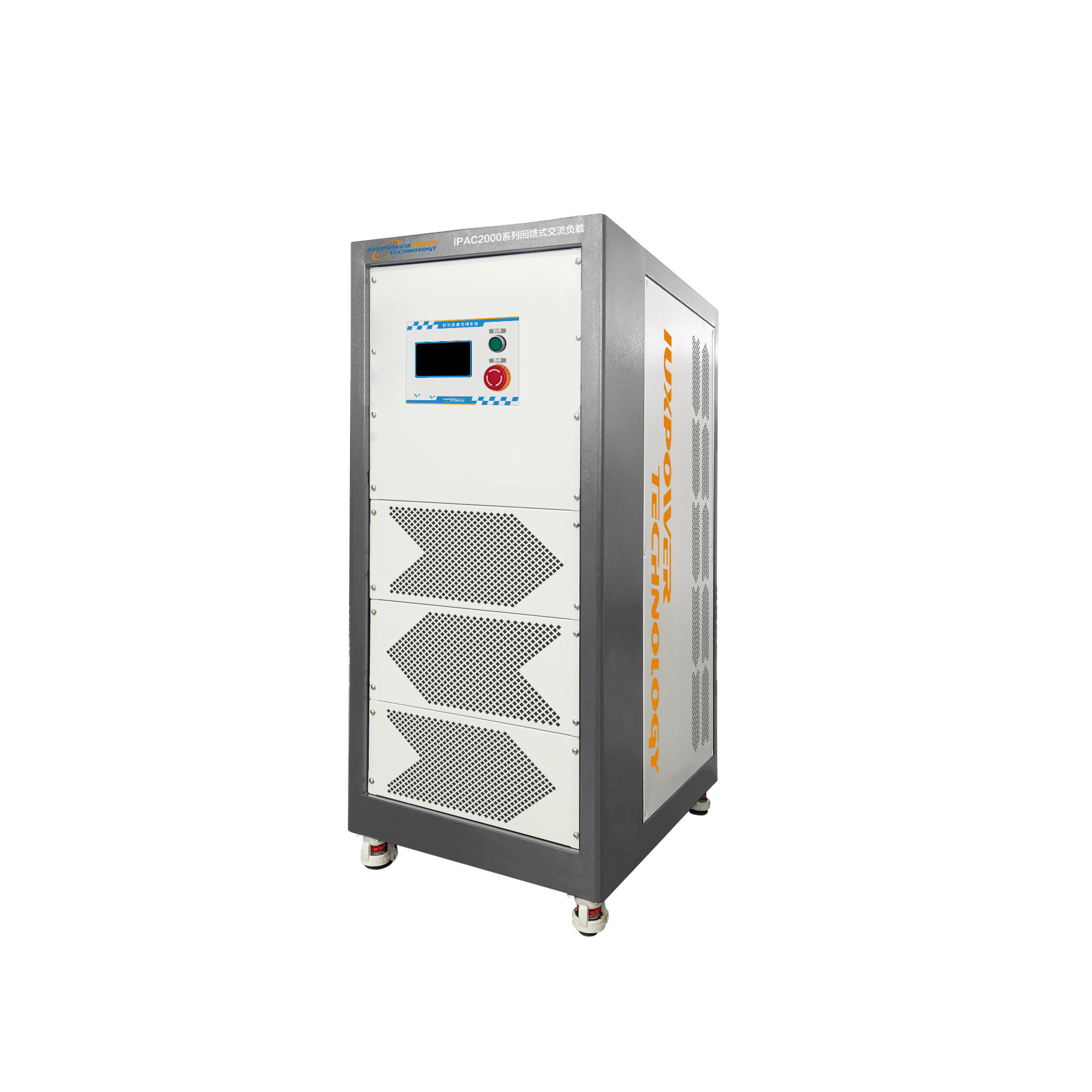

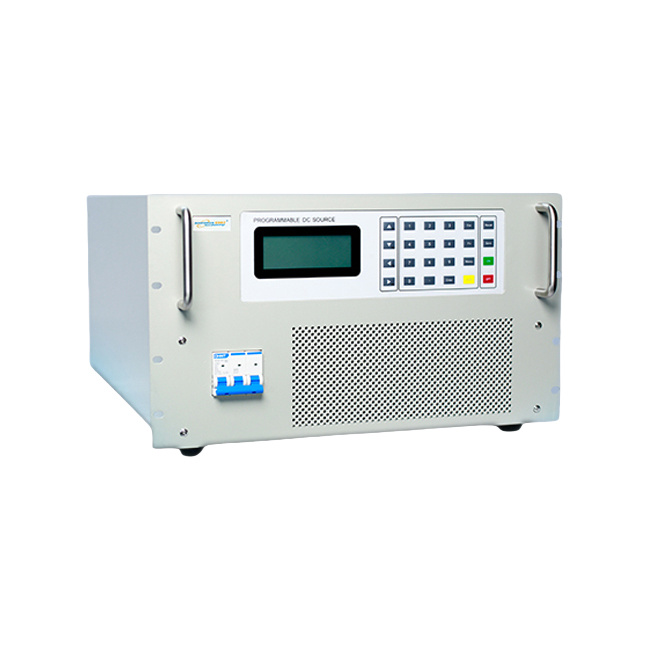

我们的产品

产品已⼴泛应⽤于船舶制造与维修、航空⼯业品制造与测试、电⼒通讯调试测试、家⽤电器⽼化测试、⻢达电机⽼化测试、铁路电⼒测试、新能源测试、医疗电⼦测试、低压配电配套、⻜机制造与维修、国防军⼯等⾏业领域,以及计量、质检、国际认证等国家机构和科研院所。

我们的产品

产品已⼴泛应⽤于船舶制造与维修、航空⼯业品制造与测试、电⼒通讯调试测试、家⽤电器⽼化测试、⻢达电机⽼化测试、铁路电⼒测试、新能源测试、医疗电⼦测试、低压配电配套、⻜机制造与维修、国防军⼯等⾏业领域,以及计量、质检、国际认证等国家机构和科研院所。

为什么选择至茂?

自成立以来,我们始终坚守“专业精细、特色、新颖”的经营理念,致力于通过技术创新,为客户提供卓绝的产品与服务。

为什么选择至茂?

自成立以来,我们始终坚守“专业精细、特色、新颖”的经营理念,致力于通过技术创新,为客户提供卓绝的产品与服务。

全行业技术覆盖

专注新能源与电力电子检测领域,产品应用于船舶制造、航空工业、军工等 20 + 行业,为计量质检机构、科研院所等提供专业解决方案

定制化创新能力

拥有专业研发团队,可针对新能源自动化产线、科研项目等需求,提供测控系统软硬件定制设计与技术咨询服务

新闻资讯

了解至茂科技动态与行业资讯

浙江省宁波市宁海县越溪置信智造谷17幢(至茂科技)